Neon Signs and the Importance of Transformers

Neon sign transformers are step-up transformers whose secondary windings produce the high voltage necessary to create an electrical breakdown in the inert gas with which the tubes are filled. After breakdown, a stable conduction channel or glow discharge is established in the gas, and the voltage is significantly reduced.

Design and Current Control in Neon Transformers

The original design of the neon transformer core prevents the current in the tube from increasing uncontrollably with increasing voltage. It is necessary to keep the current intensity within a certain, rather narrow, range, since a significant deviation of the current intensity from the calculated one (both upward and downward) will lead to changes in other calculated parameters of the discharge tube, which will inevitably affect its operability.

Impact of Current Intensity

For example, if the current in the secondary circuit is too high, the gas in the tube will heat up more, in turn heating the glass above the design temperature, which is not at all desirable for a discharge tube of this design. The electrodes will also overheat, wearing out faster and losing their performance, while significantly reducing the overall life of the discharge lamp. At the same time, operation at reduced current intensity noticeably reduces the glow intensity of the tubes.

Operating Conditions

During normal process flow, the tube operating temperature usually does not exceed 38 – 45°C, the electrode temperature is approximately 70 – 80°C, and the luminescence is nominal (depends on the luminous efficacy of the phosphor). In order for the electrodes to perform optimally, the current flowing through them should be approximately 25 to 30% less than the stated electrode rating. When this condition is met, the electrodes are not heated above the design temperature, and the emissive layer yield is close to the maximum.

Techniques for Current Limitation

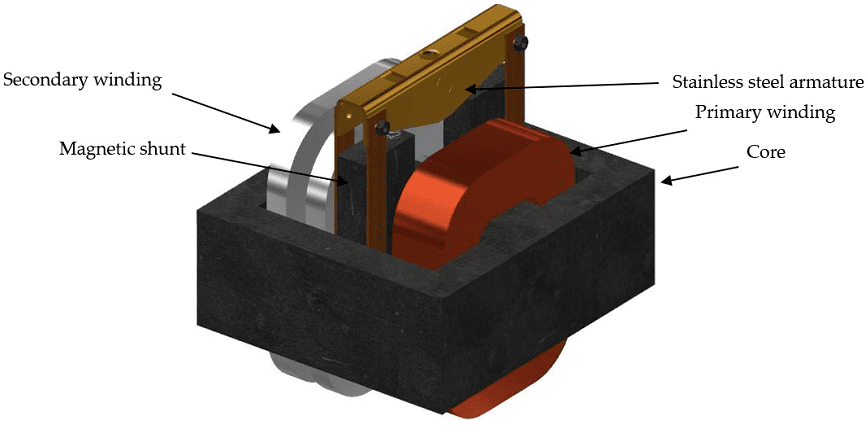

Magnetic Shunts and Energy Dissipation

How does the current limitation of the secondary circuit of a transformer take place? Technically, it is done by magnetic shunts embedded in the transformer core, which dissipate part of the electromagnetic energy produced by the primary coil and propagating through the metal core. As a result, in those parts of the core on which the secondary windings are wound, the intensity of magnetic flux is much weaker, respectively, and the current intensity in these windings is much lower.

European and American Transformer Models

Transformers for neon are divided into two large subgroups according to the method of current limitation in the secondary circuit. In the world neon industry, mainly two methods of secondary circuit current limitation are widely used, corresponding to the so-called European and American (or Asian) traditions. European transformer manufacturers traditionally follow a model in which the short-circuit current of the secondary windings is 30% to 40% higher than the operating current (factor 1.3). American and Asian manufacturers prefer a different model in which the short-circuit current is only 20% higher than the operating current (factor 1.2).

The initial adherence to one or another tradition is most likely due primarily to considerations of expediency, which, in turn, stem from the specific environmental conditions of different regions that determine the established requirements for electrical safety, as well as from the specific mentality of the population of these regions.

At first glance, the difference between the coefficients is not so great, but upon closer examination, their real expression turns out to be quite significant. Since the European style transformers (coeff. 1.3) have a higher short-circuit current, they are more efficient than American-type transformers (coefficient of 1.2). Numerically, European style transformers are 15 – 25% more efficient, depending on the rating. It is the greater efficiency of European style transformers that makes their use the most preferred in the vast majority of cases.

At the same time, the requirements for the accuracy of secondary circuit electrical load length calculation for European-style transformers are more stringent, because the range of optimal electrical load length is narrower than that for American-style transformers. However, accurate load matching is not difficult, you just need to spend a little time to measure the current in the secondary of the transformer after the load is connected. Measurement must be carried out with an instrument specially designed for this purpose.

Challenges with Gas-Light Transformers

Gas-light transformers have two unpleasant features: at low load, overheating of windings is possible, which is one of the main reasons for their failure. In turn, overloading the transformer leads to the development of high-frequency oscillations in the electrical circuit, which deteriorate the quality of line voltage. Such interference can affect the operation of capacitors, resulting in breakdowns, and protection devices, resulting in false tripping of circuit breakers.

Conclusion

Reliable operation of gas neon lighting systems for neon signs depends significantly on the operation of the power supply systems. Choosing high-quality components, including glass neon signs, can enhance both the visual appeal and longevity of the installation. By ensuring that each element is designed to function optimally under varying electrical conditions, you can achieve a stunning and durable lighting solution.